TOOLING

A complete and

and personalised support

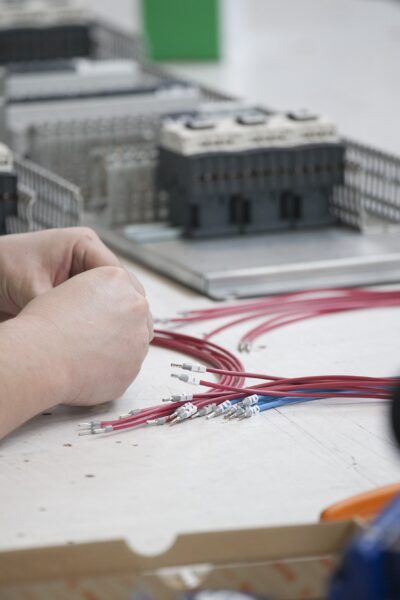

Our TOOLING and stamping experts will support you in your projects for stamped parts to offer you the tools best suited to your needs, depending on the parts to be made and your specifications. We design, produce and industrialise your cutting and stamping tools to operate them on our various production sites or transfer them to your own factories. From the study, to the co-design, to the mass production, we are there to accompany you in your production.

Thanks to our in-house tool making, we control all the stages of the tooling construction. This integration allows us to be more reactive, to be closer to our customers and to be more autonomous with regard to the means of production. We are able to produce and use different types of tools: progressive tools, transfer tools and rework tools.

R&D and co-design work

We work with our customers to adapt the geometry of the parts to the stamping process while taking into account our customers’ functional criteria. Thanks to our complete control of the process, we can guarantee that our products will meet our customers’ specifications. Our teams have complete autonomy to develop and design the TOOLING necessary for the production of parts with our customers.

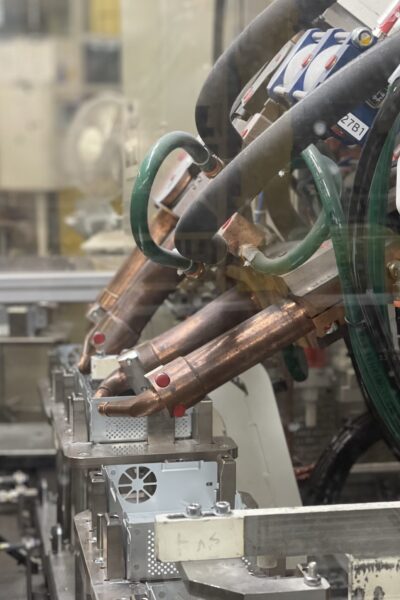

In die Solutions

In the Groupe AIM, we are developing our know-how to integrate more and more technology into our tooling, such as crimping, tapping or stapling. This allows us to offer our customers ever more economical solutions for the manufacture of parts. This solution completes our activities and allows us to be more autonomous in the production of tools.