Sheet metal work

Technical parts and sub-assemblies in fine sheet metal

Within the Groupe AIM, we have over 20 years of recognised expertise in the production of technical parts and sub-assemblies in fine sheet metal.

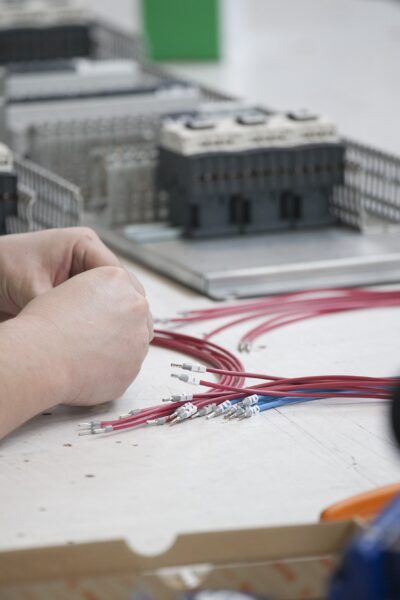

Our production teams, our engineers and technicians from the Industrialisation, Quality and Logistics departments, improve our industrial tool every day to adapt it to the needs of our customers and to the most demanding technical constraints (tolerance, appearance, complexity, etc.).

Our services

Our flexible and complementary machine park allows us to deliver tailor-made solutions, from the single part to the complete assembled, integrated and painted unit.

- 3D software and off-line programming

- Cutting: laser, punching and combined laser and punching of flat metals (steel, stainless steel, aluminium, brass, copper, HLE and THLE …),

- Manual and robotic bending

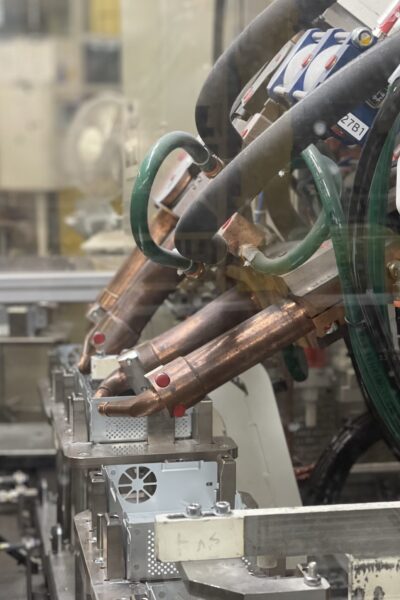

- Welding (manual, robotic, spot welding)

Mastery at the service of the customer

The use of 3D software and off-line programming carried out prior to production guarantees the feasibility and viability of all our productions.

Our organisation allows us to manage the various manufacturing centres as closely as possible, as well as providing daily assistance to our customers in the complete development of their products.

The mastery of processes and our ISO 9001 quality commitment allow us to offer a high level of quality and repeatability.