The Assembly

A complementary

technology

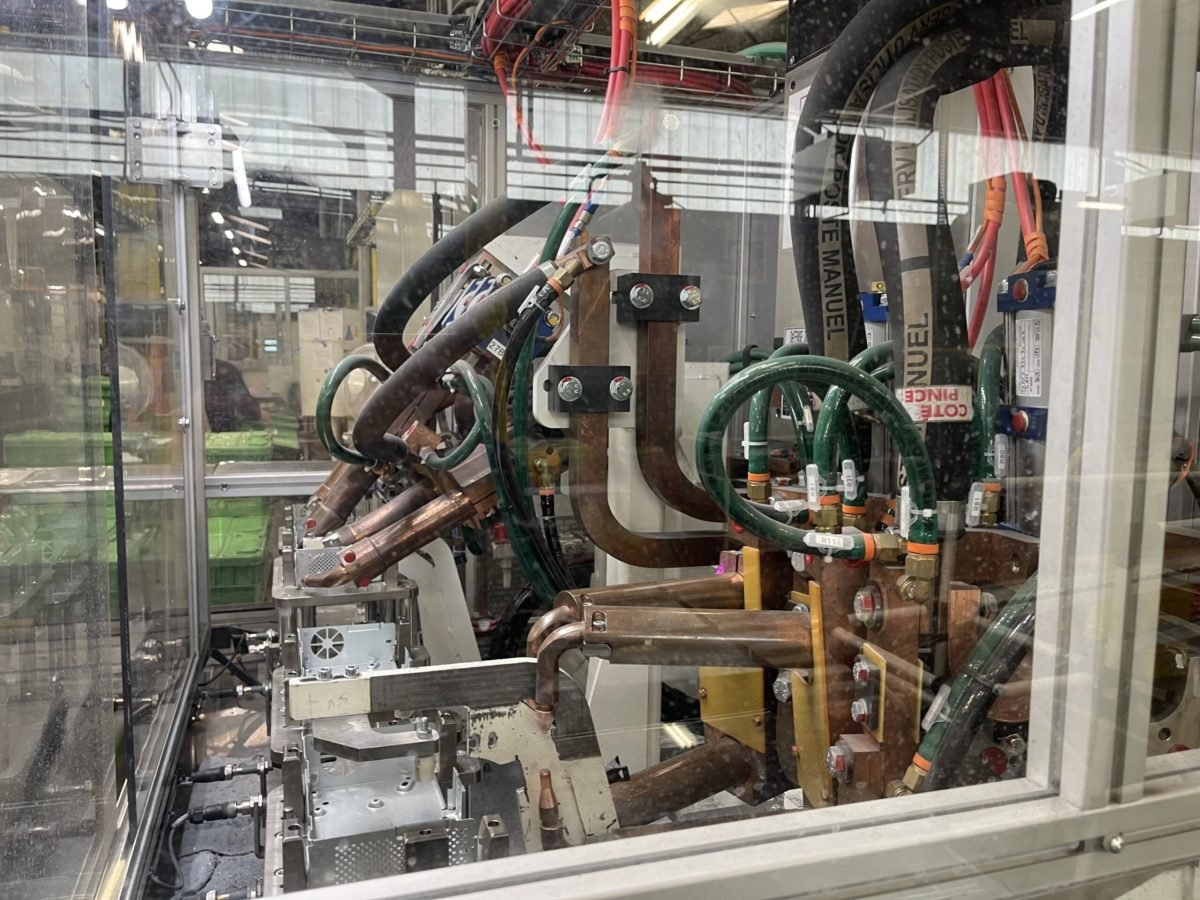

In addition to traditional cutting and stamping, we offer complete assembly solutions for sub-assemblies and modules.

Commercial or in-house manufactured components are combined with robotic processes to optimise production costs. These processes are suitably adapted to the customer’s products on generic production means or on specific dedicated lines.

Key figures

- 2 robotised assembly cells in line

- 1 assembly line with spot welding and final camera control

- 1 laser engraving station with final camera control

We bring added value to products by combining processes:

- Mechanical assembly: crimping, clinching, clipping of plastic parts, screwing

- Marking: laser, engraving

- Welding: spot welding, laser, TIG

- Degreasing

- Fluxing for NOCOLOK brazed parts

Each new product is a special case for which we develop solutions in-house or with our partners.

Quality control

All assembly operations are controlled by regular checks during the manufacturing process.

A final camera inspection is carried out at 100% for a total guarantee of the quality of the finished parts.

Find out

about our subsidiaries

Have a question?