Folding

Folding is an operation to deform previously cut flat metal.

The cut flat blank is placed on a die, also called a vee, and is pressed against stops. In a second step, the punch, or counter-vee, applies a force suited to the thickness, material grade and desired angle.

We use several bending techniques:

- Folding in the air, the most common solution requiring the taking into account of the elastic return

- Strike folding, particularly used to make precision folds but requesting much more power

- Panelling, lateral folding force, particularly designed for large parts

Key figures

- 31 numerically controlled folding machines

- 2 robotic bending centres

- 1 seaming machine

Historical knowledge

in folding

Within the Groupe AIM, we are able to develop a wide range of specific tools, covering a wide range of folding needs including the most technical products.

The know-how of our folders is a strength within our company. Thanks to in-house training and control protocols, we can guarantee our customers quality and precision in folding, making the Groupe AIM a recognised player.

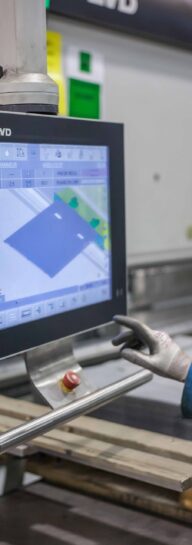

Our machine park, with around thirty numerically controlled folding machines, enables us to produce a wide variety of parts, from one-offs to large series, of various thicknesses and material grades and of different dimensions. The automatic control and correction equipment provides ease and speed of execution and a better guarantee of conformity.

Cutting-edge technology in our plants

To improve our production performance, we have supplemented our manual folding machines with cutting-edge production tools.

We have equipped our production sites with robotic folding machines to improve our technical performance and automate our processes. Robotic folding and panning machines provide us with highly flexible technical solutions with reduced production times.

Find out

about our subsidiaries

Have a question?