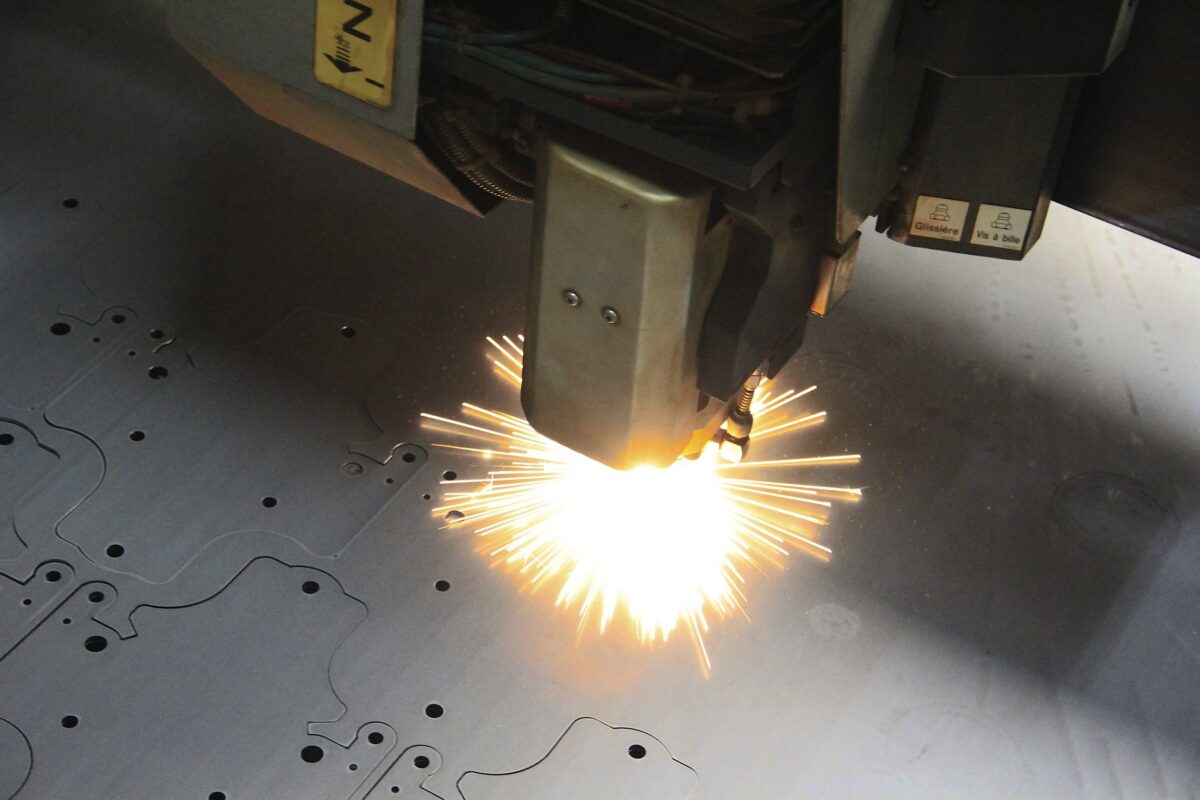

Cutting, punching and

laser

The first step

of transformation

The first skill of a “sheet metal worker” is cutting the metal into sheets. This first stage of transformation consists of cutting the metal with a laser beam and/or multiple punches to create shapes and patterns.

Key figures

- 5 CO2 lasers

- 1 fibre laser

- 8 punching machines

- 2 combined lasers

A complementary fleet

We rely on different cutting solutions: laser, punching and combined. These complementary technologies enable us to suit our production resources to the technical and economic requirements of our customers and the logistical reality of their markets.

Our automated cutting centres equipped with loading and unloading warehouses provide the flexibility and responsiveness to meet customer requests. This recent, high-performance, flexible and complementary machinery enables us to cut metals such as steel, stainless steel, aluminium, brass, copper, etc. Thanks to the various investments we make to be at the cutting-edge of technology and to improve our solutions, we can suit the most demanding technical constraints (tolerance, appearance, complexity, etc.).

Find out

about our subsidiaries

Have a question?