Assembly and

integration

Assembly is an activity that allows the assembly of different sheet metal parts, and also of purchased components, to meet the final needs of the customers. It is usually the last processing operation before the finished products are shipped to our customers.

As a continuation of sheet metal fabrication, assembly has several specificities and different skills:

- Mechanical assembly of sheet metal components: pop riveting, crimping, with screws, gluing, torque tightening

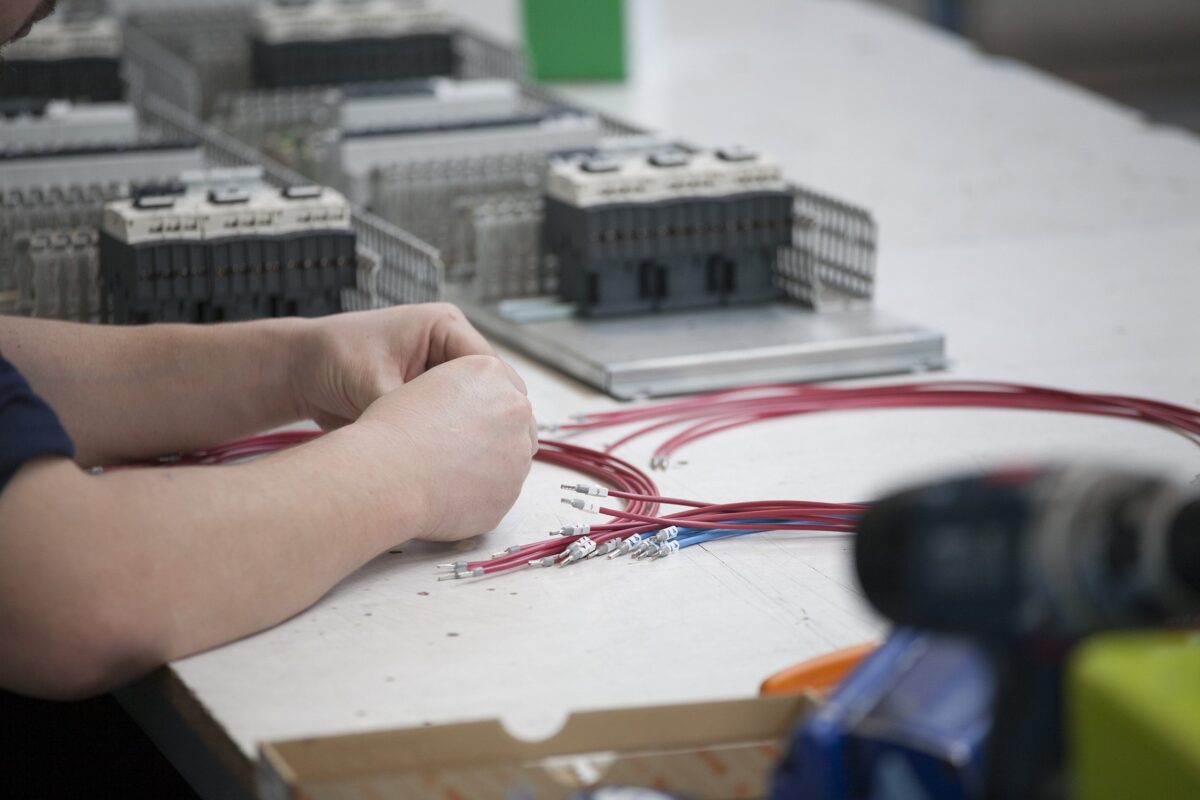

- Preparation of electrical sub-assemblies: production of our cables, electrical harnesses

- Electrical wiring on painted sheet metal assemblies

- Electrical functionality test on integrated and wired assemblies

- Endurance test on long cycles to qualify functionality and compliance with customer specifications

Key figures

- 3 sites with areas dedicated to assembly, mounting and integration

- 3000 m² of industrial surface dedicated to assembly

Know-how in the field of integration and cabling

In the heart of our factories, islands have been specially designed for the complete assembly of certain products. We are able to deliver a complete and functional product.

The know-how of our cable operators and integrators is a strong complement within our Group when our customers require an assembled and integrated sheet metal product. We master both metal processing and electrical integration.

Cutting-edge technologies in our factories

To validate our assembled products ready for use, we are equipped with the means to carry out safety and functional tests, including for specific configurations: networking, CE requirements, ESD testing, and software loading.

Find out

about our subsidiaries

Have a question?