New Investments at the IVA Site

Our IVA site (72) has undertaken a series of investments this year aimed at modernizing its surface treatment facilities and improving energy efficiency. Three projects are currently underway, representing a total investment of over €500,000. This includes the installation of a cleaning system for liquid paint equipment, the replacement of a curing oven on a cataphoresis line, and modifications to the handling of parts on the phosphating line.

These projects promise significant gains in terms of energy consumption, carbon emission reduction, and increased production capacity.

Installation of a Cleaning System for Liquid Paint Equipment

To improve the production process on our liquid paint line, a new cleaning system for the paint equipment has been installed. This system includes a cleaning fountain as well as a solvent recycler. The main objective is to reduce solvent consumption and facilitate their reprocessing. The estimated gains from this investment are close to 70%.

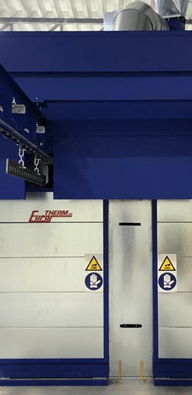

Replacement of the Curing Oven on the Cataphoresis Line

A new curing oven has been installed on one of IVA’s cataphoresis lines, bringing several significant advantages:

- Improvement of the production process,

- Reduction of odors in the workshop for employee comfort,

- Optimization of energy consumption with a hybrid oven (gas + electricity),

- Estimated 30% reduction in gas consumption,

- Reduction of carbon emissions, aligning with our MiniWatt initiative.

Additionally, a major reconditioning is planned for this line with the replacement of the cooler and the two pumps of the cataphoresis bath.

Modification of Part Handling on the Phosphating Line

To meet the increased capacity demands of our clients, modifications will be made to the phosphating line. The part handling carousel will be changed to double the production capacity.

These investments demonstrate our commitment to improving our production processes while reducing our environmental impact. The anticipated gains in energy efficiency and production capacity will not only meet client needs but also strengthen the workshop’s position as a major player in the field of surface treatment and industrial painting.